Preventive Maintenance

Congratulations on your decision to install a home standby generator! This is a fantastic investment for your home, providing you with reliable power for many years to come. After installation, many customers ask, “What do I do next?” The good news is that the answer is “not much.”

In the event of a power loss, your standby generator will do all the work automatically, offering you hands-off peace of mind. However, it’s important to remember that, like any machine, your generator requires periodic maintenance to ensure its dependability. Generators have numerous internal moving parts, all of which are critical to the unit’s overall performance. Without proper maintenance, these parts can degrade over time, reducing the generator’s functionality and reliability. Regular upkeep is essential.

To ensure your generator operates safely and dependably for years, Gen-Tech offers comprehensive annual preventative maintenance packages. Many companies also require proof of annual maintenance to honor product warranties, making regular servicing even more crucial.

Starting With the Engine!

The heart of your generator is its meticulously designed engine. Just like a car, your generator requires key elements—lubricating oil, a steady air supply, and a spark—to function properly. However, unlike your car, your generator only runs during power outages or its weekly test cycle. Your standby generator features an aluminum engine that excels in heat transfer, keeping the unit cool even under heavy load during midsummer outages. But in cooler months, aluminum can attract moisture from the atmosphere, which may collect inside the engine.

While this moisture is usually not an issue on a day-to-day basis, prolonged accumulation can compromise the engine’s lubrication system. To avoid this, it’s crucial to change the oil annually and run the unit under load occasionally to generate sufficient heat. Generators in damp climates or cold regions are especially susceptible to condensation buildup. Regular annual maintenance by Gen-Tech ensures that this moisture doesn’t become a problem, keeping your generator in optimal condition year-round.

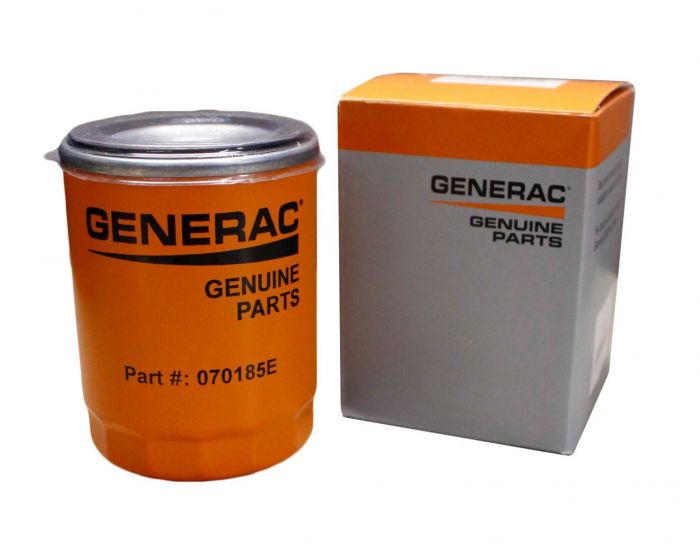

Changing the Oil

We exclusively use full synthetic oil for the generators we service. Synthetic oil is designed to keep water molecules separate, ensuring that condensation does not mix with the oil. This separation allows the moisture to dissipate through heat generated during load tests or through routine annual oil changes.

In contrast, conventional paraffin-based oil tends to mix with water, leading to undesirable results. When water mixes with conventional oil, it can create a foamy, tan-colored substance that significantly hampers engine performance. By using full synthetic oil, we help protect your generator’s engine from moisture-related issues, ensuring it runs smoothly and efficiently for years to come.

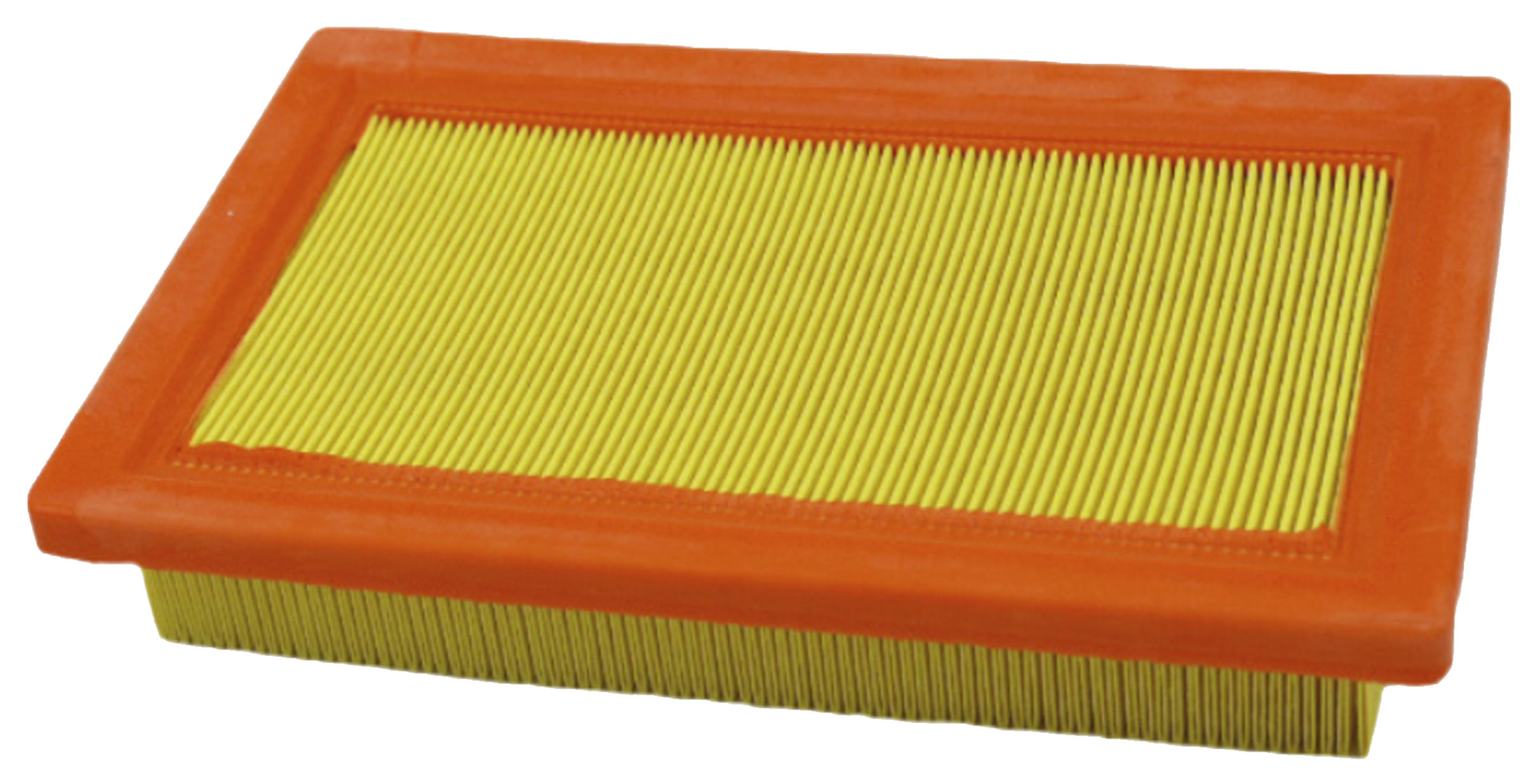

Changing the Air Filter

Many customers ask us why we also change the air filter annually. The simple answer to this question is moisture. Yes, your air filter will look like new, but in truth, moisture collects in the air filter over time and restricts airflow to the engine. Simply stated, lower airflow equals less performance.

Changing the Spark Plugs

Contrary to popular belief, spark plugs in natural gas-fired engines can degrade faster due to the acidic nature and impurities in natural gas. Within just a year, spark plugs can appear sand-blasted and corroded.

After several years, these worn spark plugs may misfire, compromising your generator’s dependability. Annual spark plug changes are a simple yet effective way to maintain your generator and ensure its reliable operation.

Adjusting the Valves

Generator engines feature mechanical valve trains with extremely tight clearance specifications, between 0.002 – 0.004. Over time, as these parts wear down, the valves can become tight and remain partially open, leading to hard starts and poor performance.

Manufacturers recommend adjusting the valves after the first year of service and then every two years. At Gen-Tech, we go the extra mile by adjusting valves annually as part of our comprehensive maintenance package, ensuring your generator operates at peak performance.

Checking the Frequency

After servicing the engine, we run it at normal operating speed and check the “HZ” or frequency. The frequency of electrical service in the US is 60HZ, which is relevant to the engine speed. If the frequency of your generator is high, then the engine is turning too fast. If it is low, the engine is turning too slow. Damage to your electrical system and or electrical devices can occur if the proper frequency is not present. We check and adjust the frequency annually.

The Generator

The generator is made up of a rotor “moving winding, a stator “fixed winding” and a voltage regulator. Most generators use slip rings and brushes to control the field, which in turn controls voltage output. The rotor is driven by the engine and is supported by bearings, while it is cooled by a fan. All of these components are exposed to the elements, which can lead to rust, corrosion, stalling, or a number of other functionality issues.

With a Gen-Tech maintenance service, we inspect all components of the generator and use a special synthetic grease to protect all of the wire terminations as well. We also tighten every connection in the generator, junction box, and transfer switch.

Checking the Voltage

As previously discussed, checking the frequency is important to maintaining your generator, but the second part of making “clean” power involves testing the voltage. After adjusting to the proper frequency, we then check and adjust the voltage of your generator. Standard US voltage is 120/240 volts. Any voltage above or below this measure can cause damage to your electrical service and devices. The most common items to be damaged are TVs, computers, control boards in furnaces, washers, dryers, garage door openers, and microwave ovens, to name a few.

Checking the Control Board

Your generator features a sophisticated digital control board, which is basically a computer that makes everything function properly. The control board is dependent on a good 12 Volt power supply. Upon installing your generator, the control board is set to function independently and should not require any further adjustments.

If you need to adjust the settings, please consult a professional and always refer to your owner’s manual, following all instructions. Our team checks the overall programming with each annual service to make sure your system is set properly and installs any updates when necessary.

Checking the Battery

Your generator uses a lead-acid battery similar to your car’s, but the key difference is that the generator’s battery is more frequently charging than in use. This constant charge, coupled with exposure to the elements, can lead to corrosion and overheating.

Overheating occurs when the lead plates deteriorate and cause internal shorts, leading the charger to overcompensate for low voltage. This not only damages the battery but can also harm the control board, resulting in costly repairs. To prevent these issues, we recommend changing batteries every four to five years. During our annual maintenance checks, Gen-Tech load tests your battery, cleans corrosion from terminals, and applies synthetic grease to prevent future corrosion.

Checking the Wiring

Your generator system has extensive wiring both inside the unit and in the conduit that runs through your home to the transfer switch. There are many electrical terminations between the generator, transfer switch, and panel. If not properly maintained, wires can become corroded, loosen, and deteriorate over time. It is important to check the wiring in your generator annually and tighten any wires that may have come loose.

Load Testing

We often hear from new customers that their former service company never came in the house or performed a load test on their generator. A generator can be started manually from outside to check the mechanics, but this will not test if your unit will function properly during an outage. In order to make sure your generator is fully functional, we must simulate a loss of power and transfer the load to the generator and back to the utility. Load testing your generator is an important way to ensure everything is operating as it should.

Protecting the Housing

One of the most commonly overlooked parts of generator maintenance is the exterior: the housing, locks, and vents. Neglecting these can lead to corroded locks, rusted housing, and frozen hinges, which prevent the cover from opening and allow water to leak into the generator.

Issues like these typically arise when generators go 4-6 years without maintenance. During our annual service, Gen-Tech applies synthetic grease to all hinges, locks, and bolts and treats any rust to slow its progression and prevent further damage.

To prevent rust, generator owners can apply a coat of high-quality automotive wax to the housing yearly. A proactive approach in maintaining the exterior will significantly increase your generator’s lifespan and reliability.